Open-face mold generator and casting tests

Open-face molds are the simplest form of molds, but like any mold they involve a multi-step process that can be tricky to do and causes a little bit of detail to be lost each time. All molds also degrade over time and have to be retired eventually, which means if you don't hold on to the original object or that object isn't made from a super durable material, eventually you won't be able to make more copies of it.

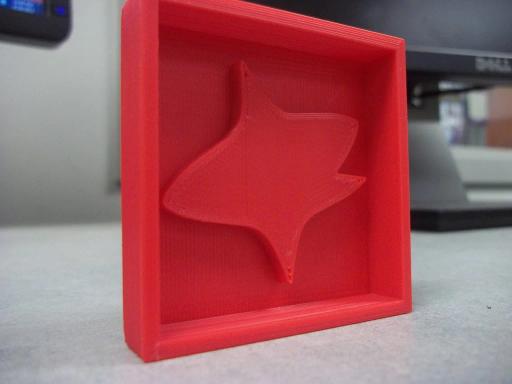

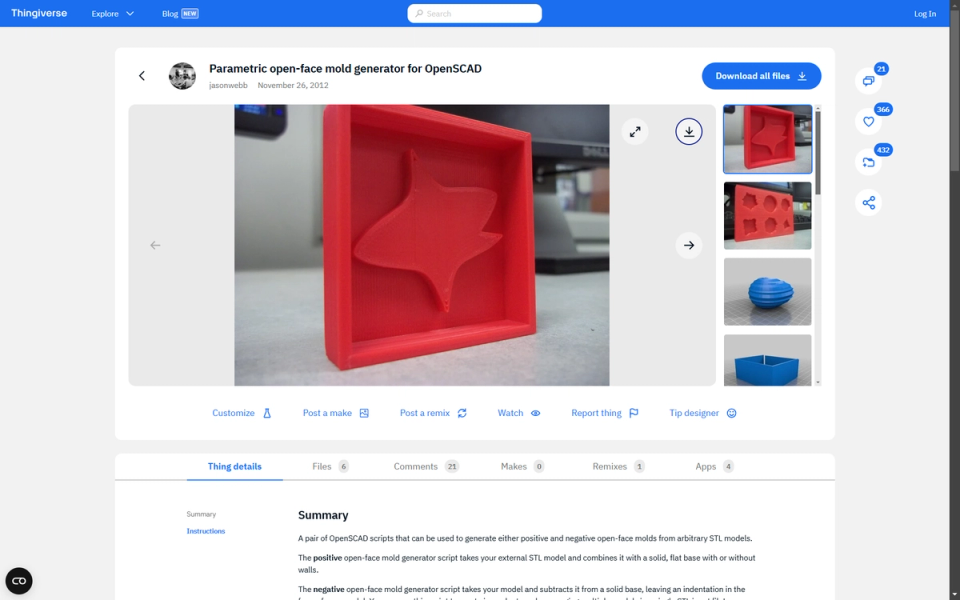

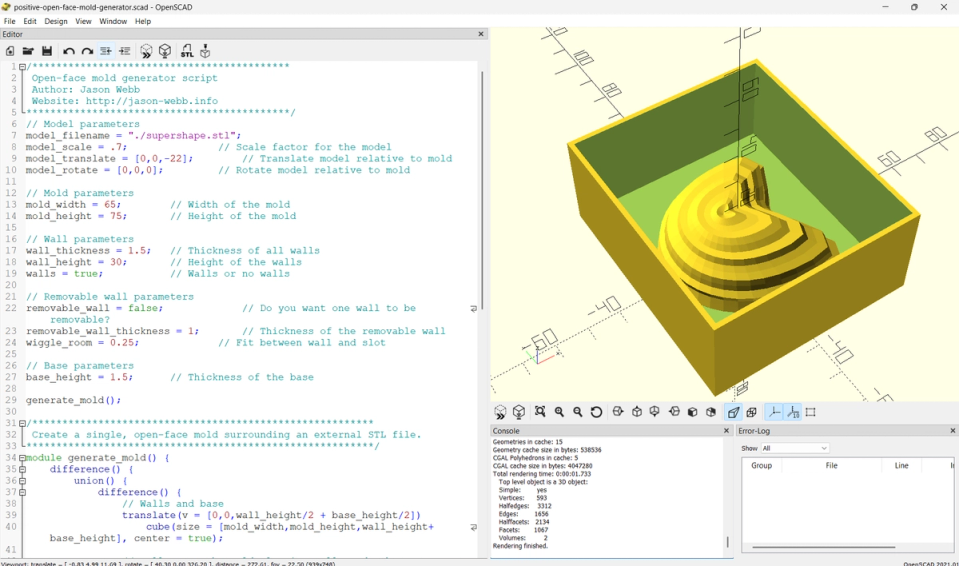

I was curious if I could use a digital model and 3D printing to both simplify the mold-making process and preserve the original object in a more pristine form. I created an OpenSCAD script that builds 3D models of either positive or negative molds for a given input model.

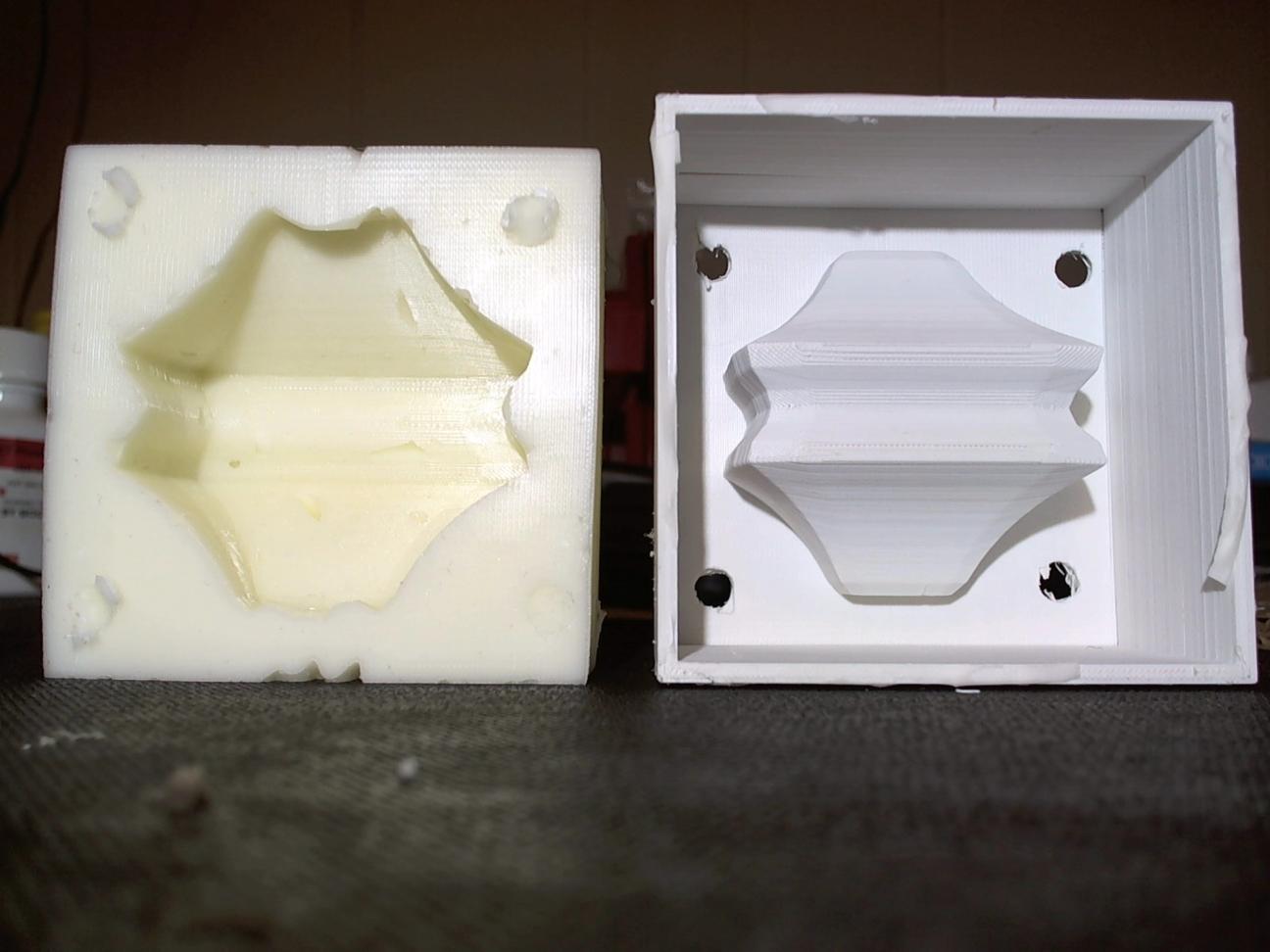

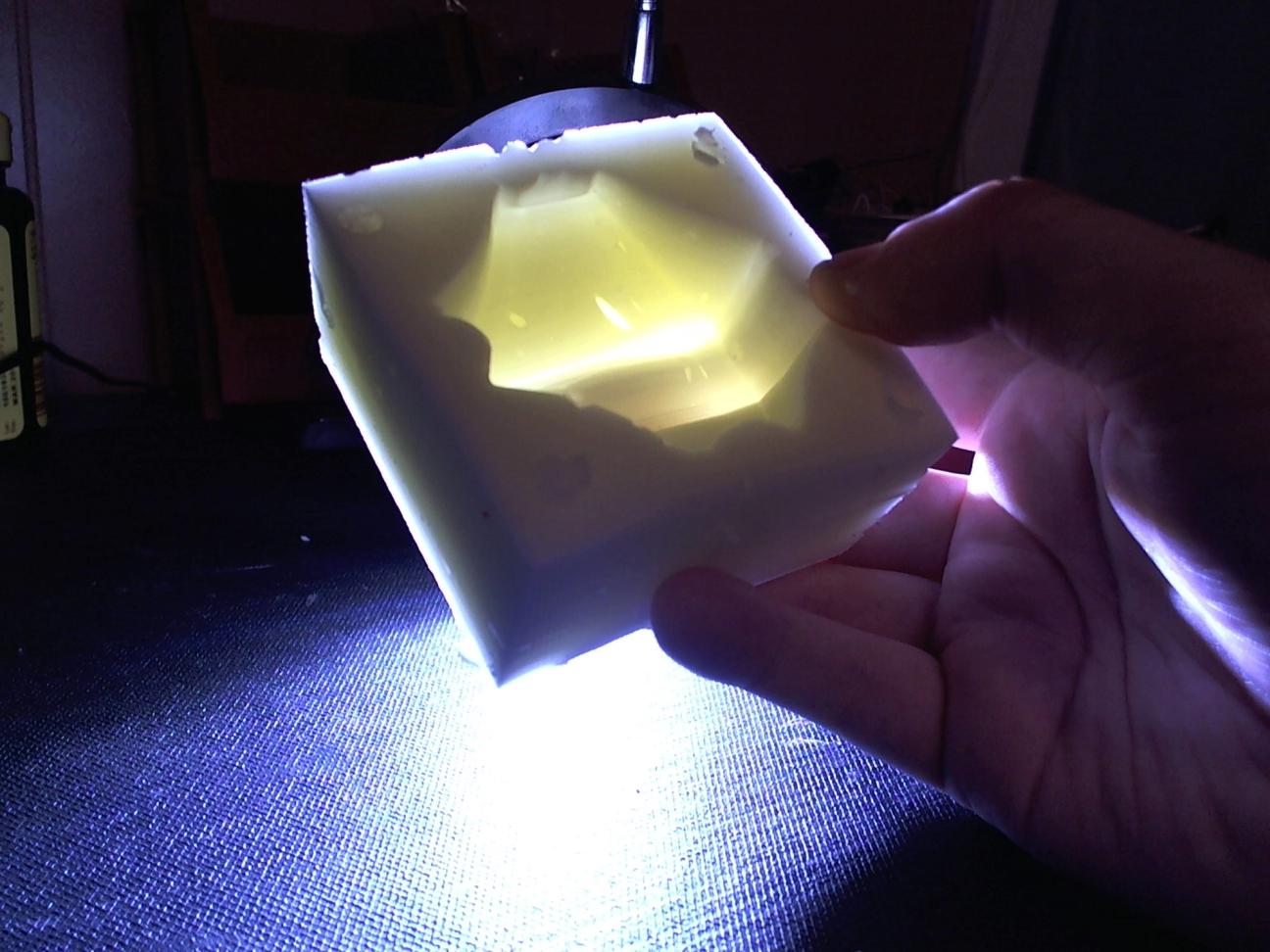

First I experimented with casting a flexible mold using Oogoo, a cheap DIY version of silicone rubber. The cast came out easily, and was detailed enough that you can see the layer lines of the 3D printed master mold!

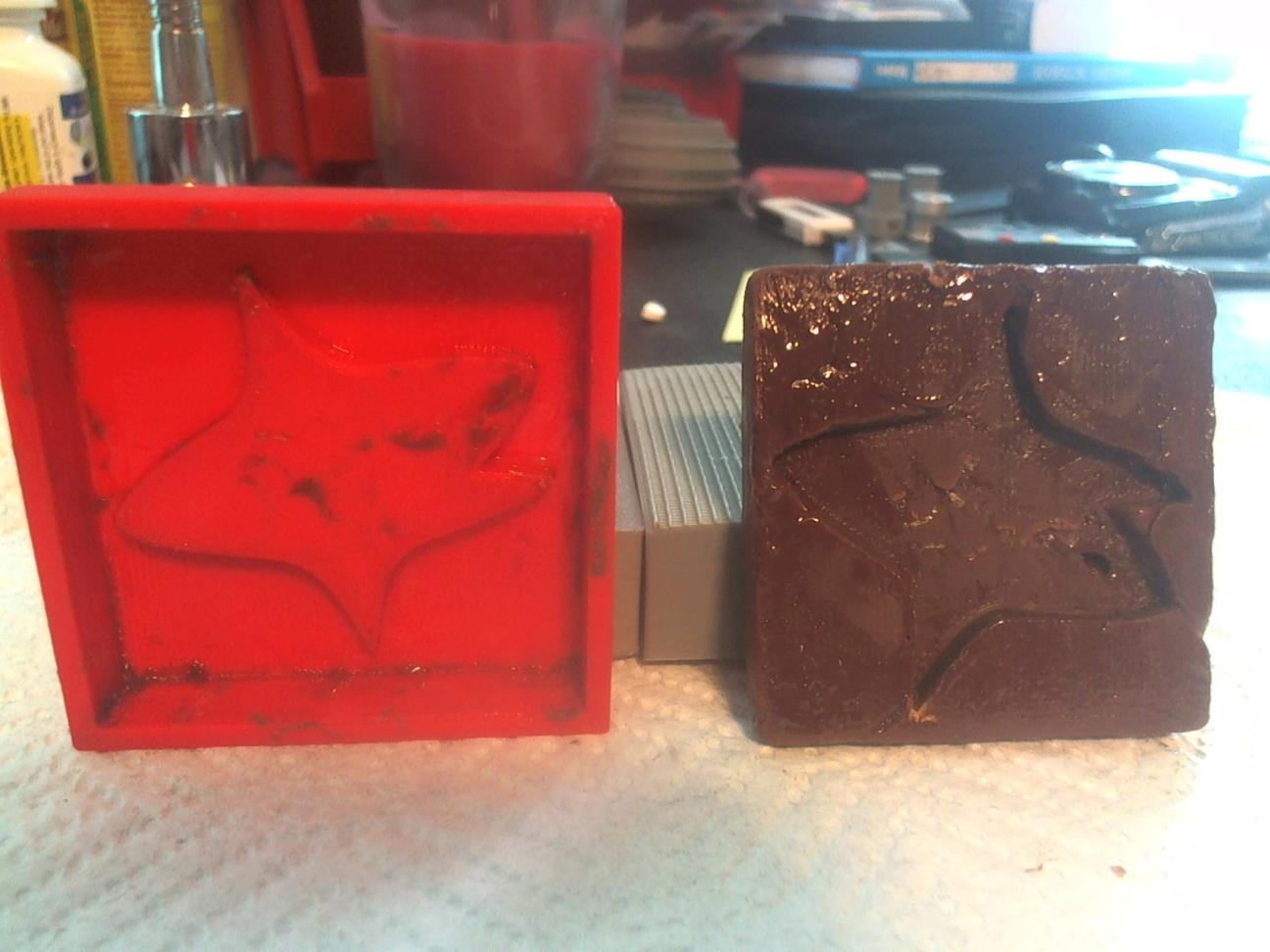

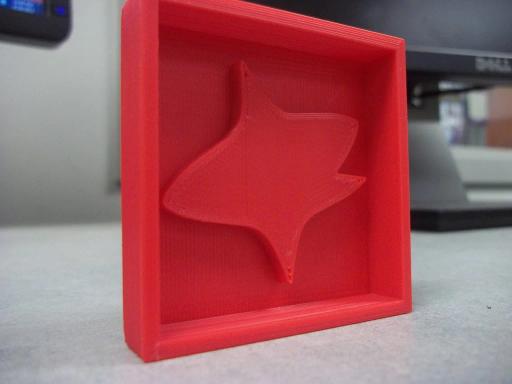

Next I printed a master mold with a positive form made from a 2D vector file. I made a very successful cast from it using Knox gelatin - the best result of the whole series!

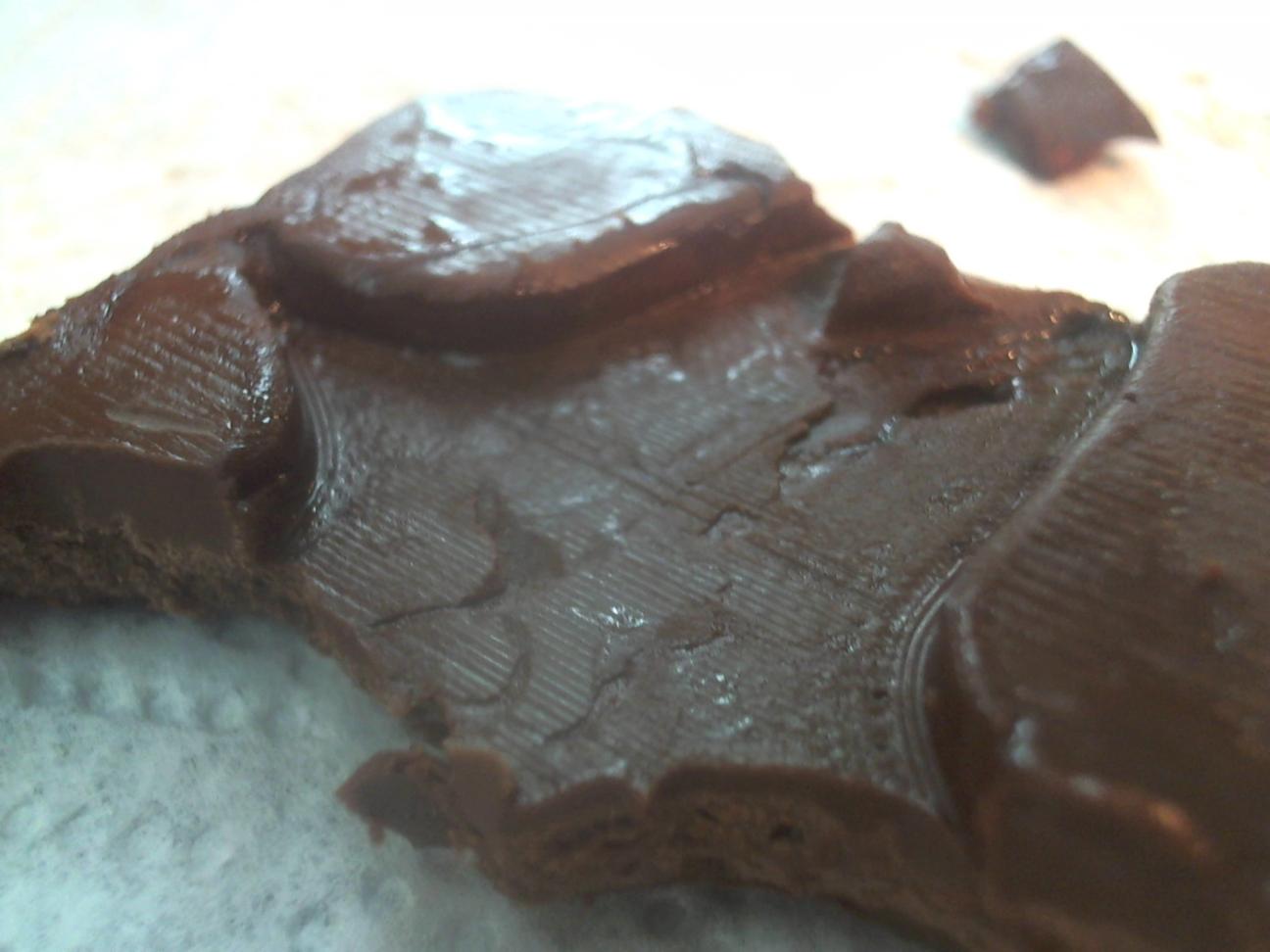

I also made a cast from this mold with chocolate, using a butter spray as a mold release. It turned out pretty well, but I learned quickly that chocolate takes some skill to work with.